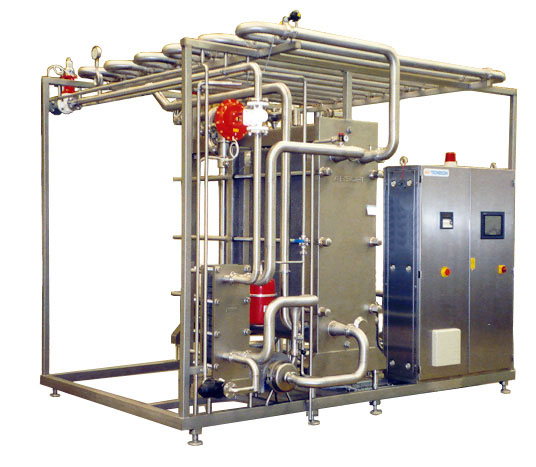

Milk Pasteurization

Application: The milk is heat-treated at 73, 75°C, for 15 seconds in order to destroy most part of the microorganisms by heat, causing minimum changes in the structure and composition of the milk. Eventual modifications in the temperature program can be considered, according to the milk final destination - cheese manufacturing, natural pasteurized milk, yoghurt manufacturing, etc.

Characteristics: variable capacity, with high percentage of heat recovery and available in a skid.

Main components: balance tank, pumps, valves, plate heat exchangers with frame and plates in stainless steel, heating unit, flow diversion valve, tubular holder, interconnection piping and control panel.

return

return